Mega Furnace Tune Up FOR $99! BOOK NOW

How To Bring Cost Justification and HVAC Upgrades Together in Atlanta

<_>

Running a commercial property is difficult. Top management wants to postpone costs for as long as possible. Tenants and employees want comfort and convenience. You’re stuck in the middle trying to make everything run as effectively and as efficiently as possible.

Still, if you don’t control the money supply for major purchases, you’re likely to hear “one more year” to try and get a little more out of existing HVAC equipment. Worse, that same line may be used year after year.

While maximizing the useful life of existing equipment is the most financially prudent option, it can allow serious issues to arise as equipment continues to fail. And in some cases can have devastating results. Imagine a computer room air conditioning system failing during a heat wave. Can you really afford a meltdown with your computer system?

While management usually understands the need for replacement when equipment has failed, it can be a little more difficult when upgrading for efficiency. High efficiency HVAC equipment usually comes with a higher initial price tag. But that cost can often be justified by the difference it will have on the monthly utility bills in the coming years.

To management, that explanation is often just talk. Sure, it makes sense in theory. But they only focus on the bottom line: what will it cost me today? And large numbers can often be difficult to take.

Many equipment manufacturers have online calculators that can give you a good estimate of annual savings for replacement of HVAC equipment with various SEER, EER, or AFUE ratings. These can be a good starting point for comparison of equipment selections.

But in doing a life cycle cost estimate for HVAC equipment, it is easy to overlook things that should be factored into the annual costs. Repairs, replacement parts, and labor rates are all hidden costs. Warranty periods can provide work at no cost if under contract, whereas work outside of contractual obligations can quickly add up.

Simple things like what type of refrigerant is used in chillers, or oil versus oil-free equipment can impact costs. Special permits and redesigns can also play a part in ongoing maintenance. All of these costs need to be considered carefully in a lifecycle cost analysis.

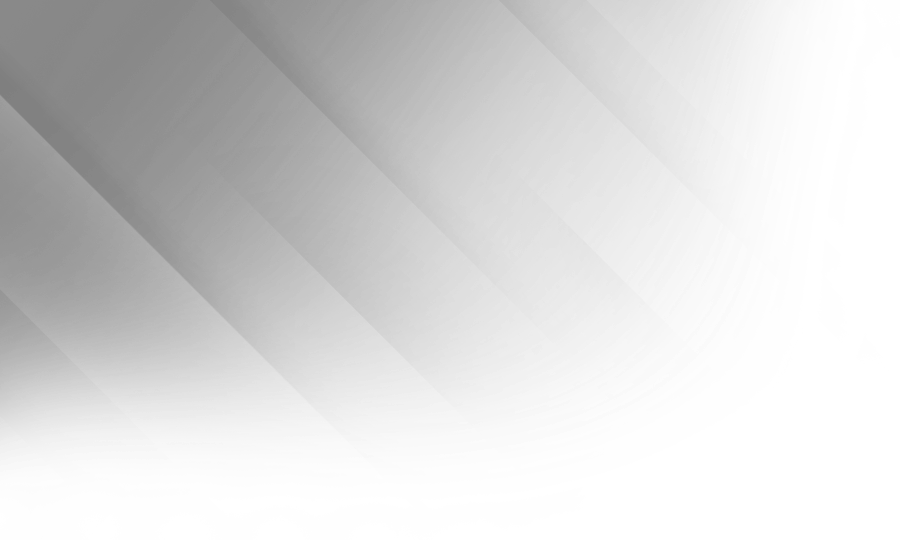

HVAC Upgrades in Atlanta

Have questions about upgrading your HVAC equipment? Are you ready to take the next step? and let us help you!

Heater on the fritz? Frustrated with plumbing problems? R.S. Andrews is just a call away!