Mega Furnace Tune Up FOR $99! BOOK NOW

Heating & AC 30 Point Tune Up in Atlanta, GA | Free Download

30 Point Heating Maintenance

Here’s what we do that sets us apart

- High Resolution (1080 dp) Deep Internal Furnace Scan

- Inspect heat exchanger and vacuum out minor rust deposits

- Pull Blower assembly or inspect the blower wheel and motor

- Visual inspection of evaporator coil

- Inspect and clean burners

- Vacuum out minor rust around burners

- Check ignition controls

- Clean flame sensor

- Measure temperature rise

- Measure blower amps

- Check blower capacitor

- Inspect flue pipe

- Test main limit switch

- Test flame rollout switches

- Test all Safety controls

- Test gas valve operation

- Check gas connections at furnace

- Check and adjust gas valve pressure (if necessary)

- Test fan control

- Test door switch

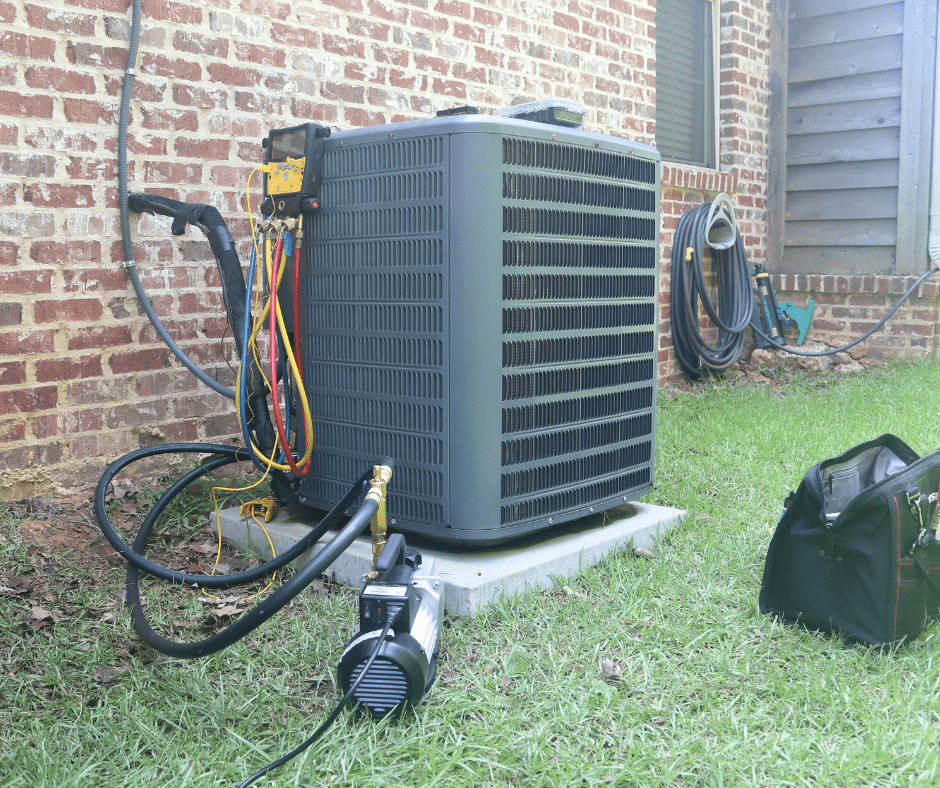

- Check and tighten all electrical connections

- Check and tighten low voltage connections

- Measure high voltage to furnace

- Test inducer assembly

- Test pressure switch

- Check thermostat operation

- Inspect ductwork

- Replace standard 1 inch pleated filter

- Update inspection label

- Clean up after completion of tune-up

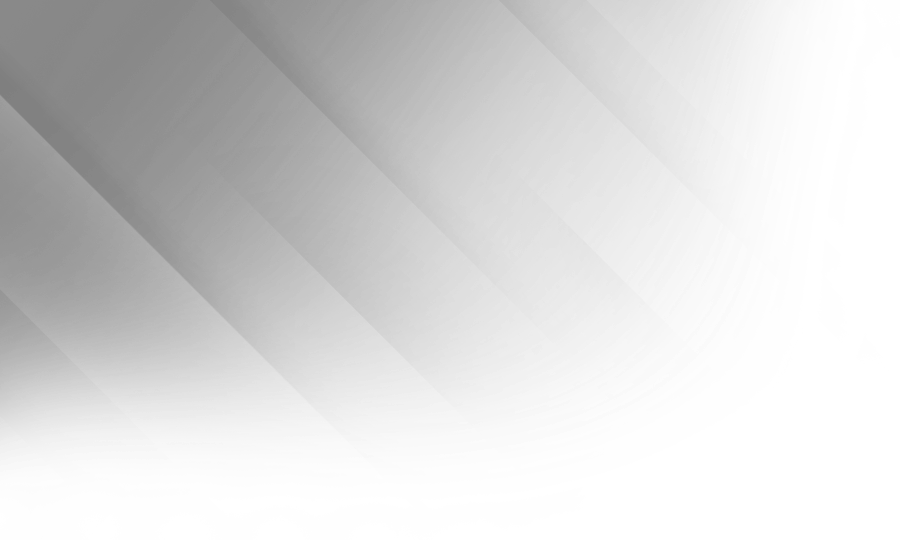

30 Point Cooling Maintenance

Here’s what we do that sets us apart

- High Resolution (1080 dp) Deep Internal Scan

- Camera scan blower assembly, inspect the blower wheel and motor

- Check blower capacitor

- Measure blower amps

- Inspect heat exchanger

- Inspect evaporator coil

- Check refrigerant charge

- Tighten all refrigerant service valve caps and covers

- Inspect condenser coil

- Clean out debris from bottom of condenser

- Inspect fan blade

- Flush condensate drain line

- Check all drain safety switches

- Check condensate pump and line (if applicable)

- Measure temperature difference across evaporator coil

- Check low and high pressure switches

- Test high voltage at disconnect and condenser

- Check and tighten all electrical connections

- Check and tighten all low voltage connections

- Measure compressor mega ohms

- Measure compressor amps

- Measure fan amps

- Test compressor run and start capacitors

- Check compressor terminal connections

- Check thermostat operation

- Replace standard 1 inch pleated filter

- Inspect ductwork

- Inspect flue pipe

- Update inspection label

- Clean up after tune-up

Heater on the fritz? Frustrated with plumbing problems? R.S. Andrews is just a call away!